The Easiest Computational Fluid Dynamics Software

FAQ

Execution

- An error "The program can't start because vcomp140.dll is missing from your computer" occurs after executing Flowsquare+.

- Can I manually choose displayed language?

- A STL file is not loaded/displayed correctly.

- Fluid flow penetrates the wall defined by the STL model.

- Can I specify an inflow boundary on a part of an STL model?

- Is there an auto-mesh capability to construct a finer mesh near the wall?

- There is always the default model appearing in my simulation.

- There is an unintentional gap between the walls specified by different preset colors in bmp images.

License

- Can I use a newer version of Flowsquare+ with my license?

- Can I get a free trial license?

- Can I still use simulation files I generated during my PRO/Two-D license period after the license was expired or I renewed the license?

Support

Execution

An error "The program can't start because vcomp140.dll is missing from your computer" occurs after executing Flowsquare+.

The VCOMP140.DLL component is usually included in general Windows Update. However, when the above error occurs, you can manually install this component with the following method.

- Please install "vc_redist.x64.exe" from "Visual C++ Redistributable for Visual Studio 2015" (https://www.microsoft.com/en-ca/download/details.aspx?id=48145).

Can I manually choose displayed language?

Yes, you can do so for version 2021R2.0 or later.

- For 2022R1.0 or later, please see here for your language setting interface.

- For 2021R2.0 or later, open .history (created when Flowsquare+ is executed in the same directory as the executable file) with a text editor. Set langFlag as 1 for English, and 2 for Japanese. For 0, the language is automatically set based on your Windows' locale and language setting.

A STL file is not loaded/displayed correctly.

Please try with our test case with a STL file such as this one to check if the procedure is correct. Then, check follows.

- The STL file has to have name "bc.stl" and stored under the input directory, along with other input files.

- STL should be loaded with a correct unit.

For example, when a STL model with a size of 1.0 (m) was constructed with the unit of (mm), the size of the model in the STL file would be 1000 (a STL file does not contain the unit information). In such case, and if you choose (m) as a unit of STL file in Flowsquare+, the model was loaded to have size of 1000 (m), which is typically out of the computational domain. In this case, the model was not displayed in Flowsquare+. You can select a correct unit for the STL model in the parameter editor window or boundary confirmation/CAD model loader explained in in this page. - A specified offset for a STL model position is too large.

In the boundary confirmation/CAD model loader, there is a button to move the CAD model to the center position of the simulation domain.

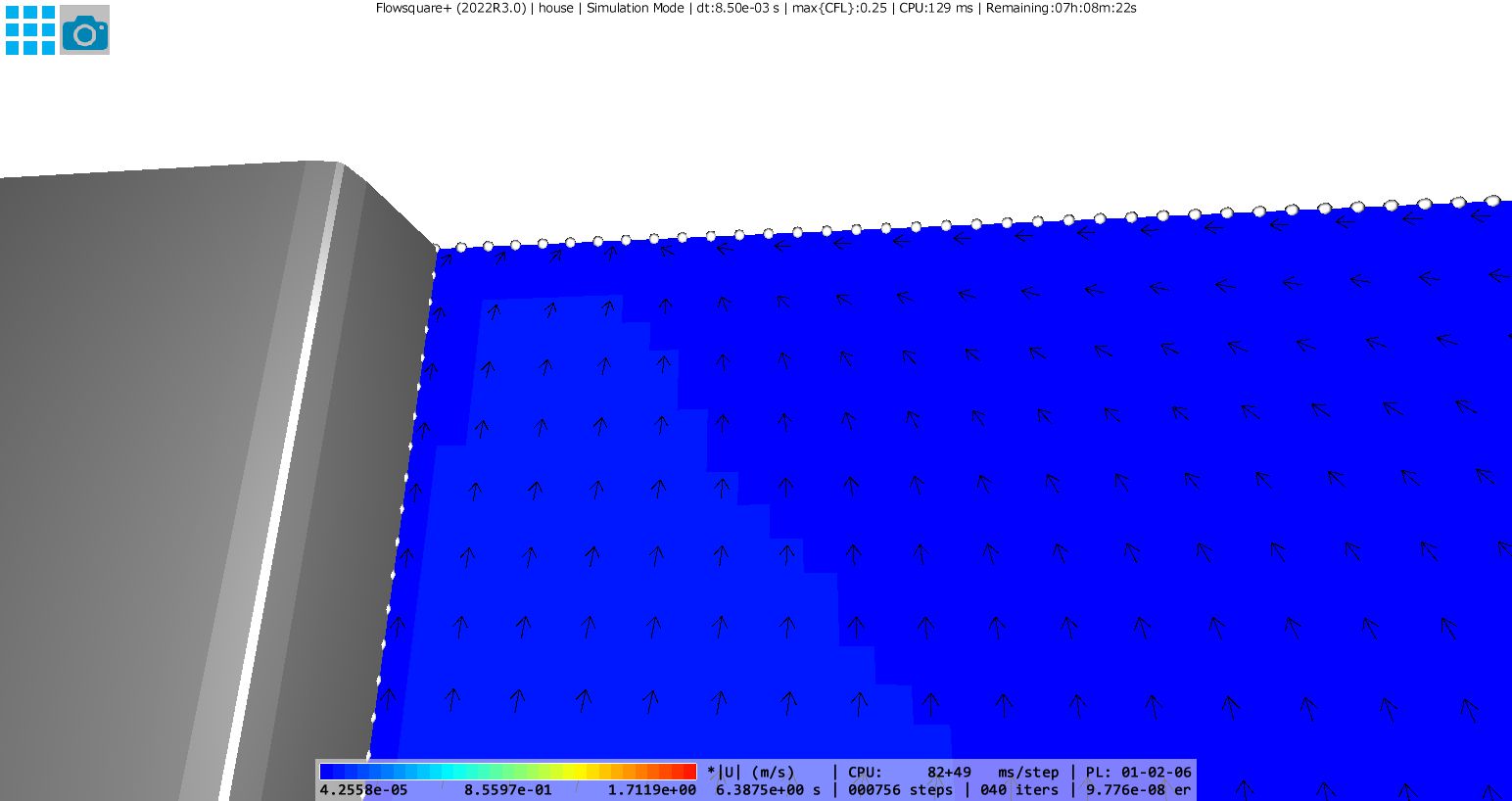

Fluid flow penetrates the wall defined by the STL model

First, please use the "Ghost/solid regions" (in tool pane) to highglight the mesh points which are acting as wall boundaries on XY, YZ and/or ZX planes.

If the mesh points in the relevant wall regions are not highlighted, it is possible that your STL model is not appropriately optimized based on 3D CAD (STL) Model and its Optimization, thereby Flowsquare+ failed to construct the wall from your STL model.

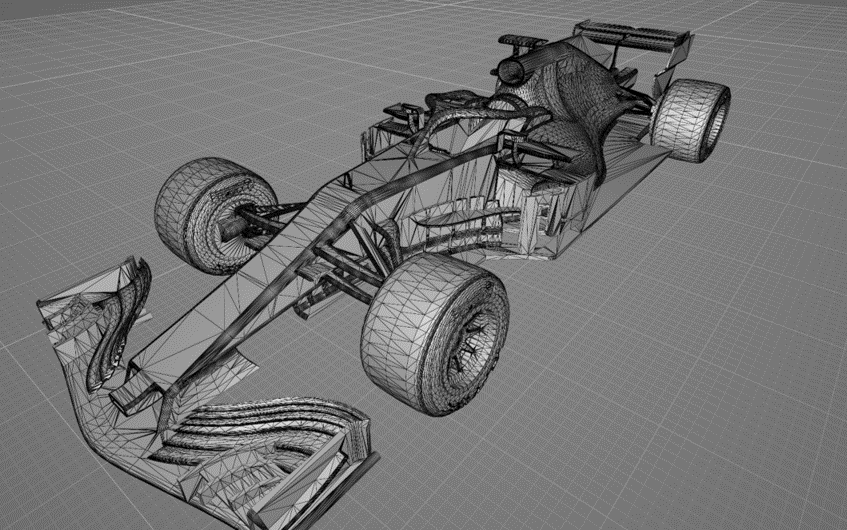

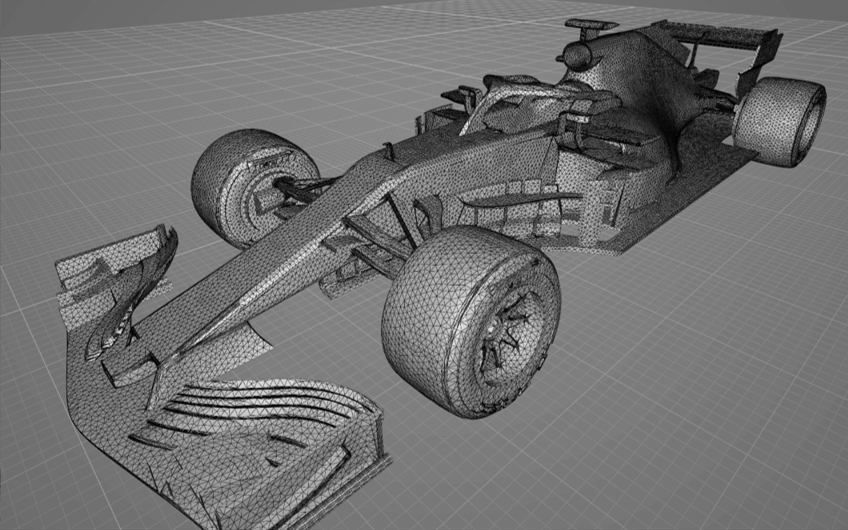

Especially, many publicaly available STL models consist of polygon meshes based on the local curvature, and the mesh size and shape change with the local model shapes.

On the other hand, uniform meshes are desired in Flowsquare+ to construct boundary conditions from the STL file.

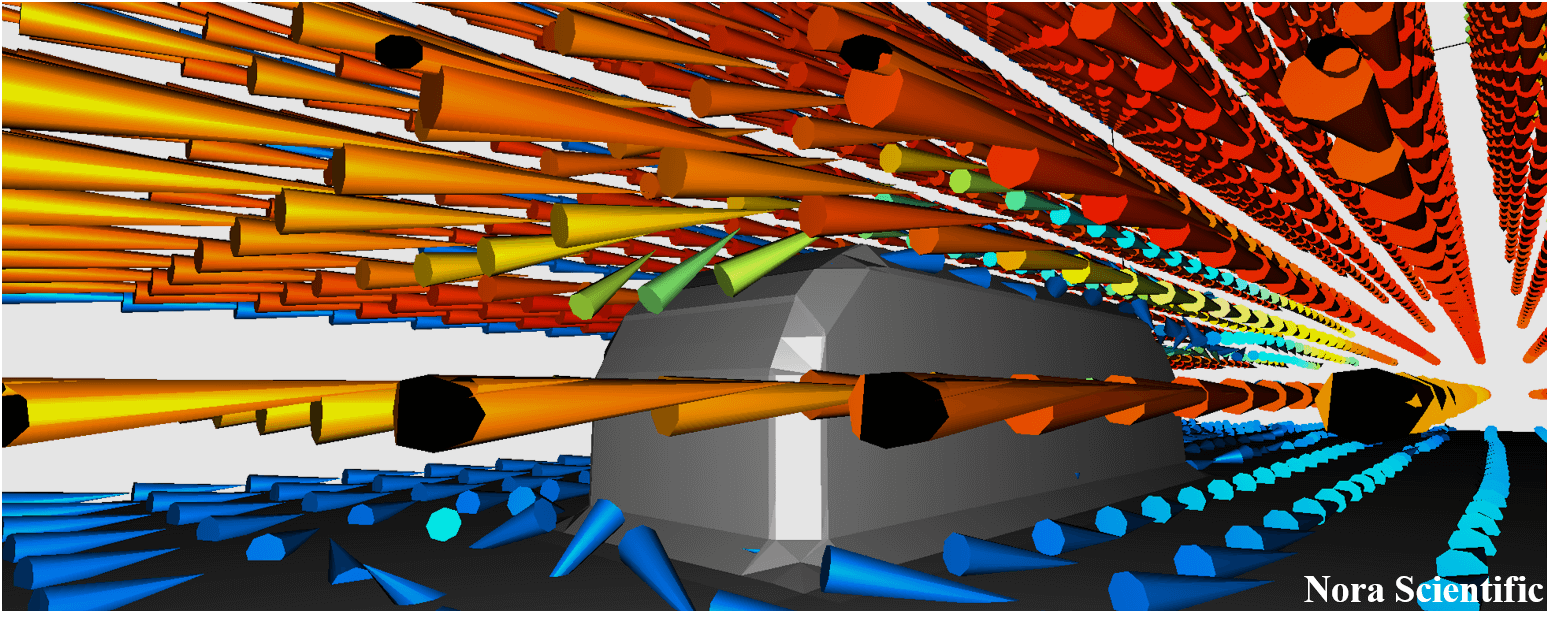

Below figures show a comparison of an unoptimized (publicaly available) STL model and an optimized STL model with mesh uniformity following the steps in 3D CAD (STL) Model and its Optimization. These models are used in an example simulation of "Wind Tunnel Test of F1 Model". Please check the mesh uniformity of your model.

Can I specify an inflow boundary on a part of an STL model?

The public version of Flowsqaure+ cannot do that. You can adjust the position of STL model to match the inflow position separately specified by preset or boundary images in the boundary confirmation/CAD model loader.

Is there an auto-mesh capability to construct a finer mesh near the wall?

The public version of Flowsquare+ uses a uniform Cartesian mesh, and does not have such a capability. The wall boundaries are specified by using immersed boundary method to express general shape of boundaries. However, the near-wall resolution for fluid flow is the mesh resolution.

There is always the default model appearing in my simulation.

Please delete the default boundary file (bcXY0.bmp) in the input directory.

There is an unintentional gap between the walls specified by different preset colors in bmp images.

Such a gap may occur due to the 3D visualization method, even when multiple walls are correctly jointed. To check whether the walls are computationally jointed, you can follow the below procedure.

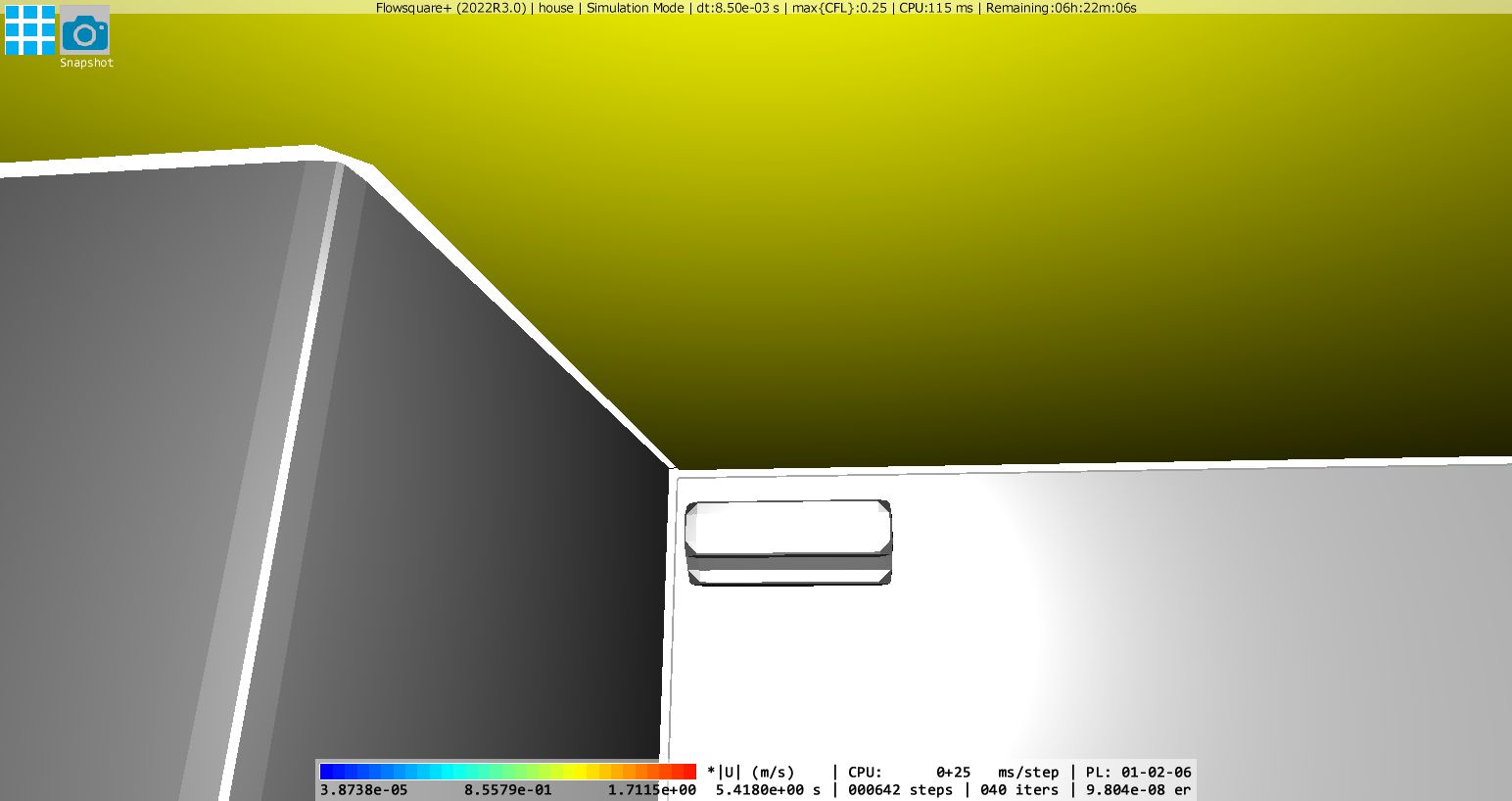

Let's use one of our example simulation cases, "AC flow simulation based on a floor plan/reference case". Run the simulation, and display all wall boudaries. Then, check the joint between the ceiling (wall boudary condition) specified by the yellow preset color and the side wall. You can clearly see (as in below figure) that there is a gap between these two wall boudaries.

Then, hide the yellow ceiling (for visibility), show the YZ-plane in front of the AC, and select  from the tool pane. This highlights mesh points act as wall boundaries (see below figure). The mesh points denoted by the grey-ish points are the mesh points specified as the wall boundary, and the two wall boundaries are correctly jointed.

from the tool pane. This highlights mesh points act as wall boundaries (see below figure). The mesh points denoted by the grey-ish points are the mesh points specified as the wall boundary, and the two wall boundaries are correctly jointed.

Therefore, in this case, the boundary conditions are appropriately set, and the gap shown is just for visualization.

License

Can I use a newer version of Flowsquare+ with my license?

Yes, you can, as long as your license is still valid. Please contact us if your license is valid but you cannot.

Can I get a free trial license?

A trial license is already included in the downloaded Flowsquare+ so you can use the software fully, except for the file output, without any charges.

Can I still use simulation files I generated during my PRO/Two-D license period after the license was expired or I renewed the license?

Yes, you can use these simulation files for analysis mode and simulation restart.

Support

Is there any technical support available?

All Flowsquare+ users, regardless of license types, can receive following support for free or for a fee.

- [Free support] General technical or non-technical questions can be asked from email or contact form (note that such questions may be listed on the website without permission, if we think they are useful for many users, with or without specific files the user attached).

- [Paid support] Non-general, user specific supports such as follows are provided for a fee. To get a quote, please contact us from email or contact form.

+ Generating or modifying user-specific Flowsquare+ input files

+ Technical support over phone/Skype/in-person

JP

JP